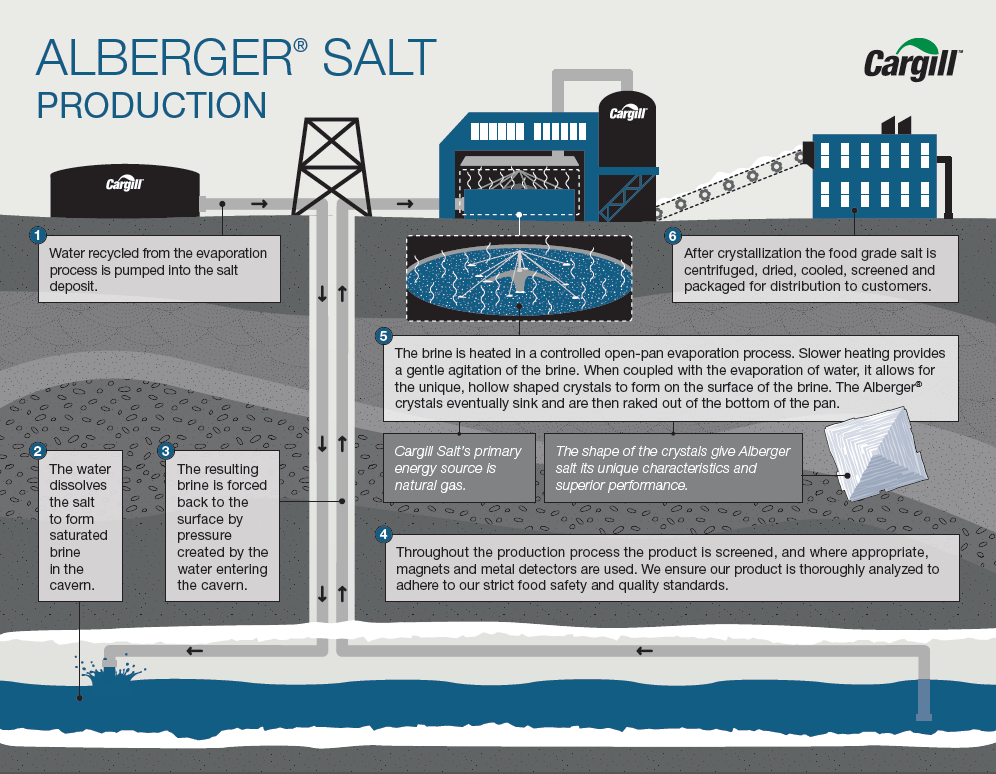

Solar evaporation methodthis is the oldest method of salt production. This water is transformed into high temperature steam which moves the alternator.

Scheme Of The Salt Manufacturing Process Download Scientific Diagram

It has been used since salt crystals were first noticed in trapped pools of sea water.

Saline water manufacturing process. Report provides a comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing. 235000008733 citrus aurantifolia nutrition 0 000 description 13. Extraction of salt from sea water manufacturing plant detailed project report profile business plan industry trends market research survey manufacturing process machinery raw materials feasibility study investment opportunities.

To make a saline solution start by bringing 1 cup of water and teaspoon of regular table salt or sea salt to a boil on the stove. Make sure you use salt that doesn t contain iodine or preservatives which can irritate your skin and nasal lining. Fluid in plastic bottles includes present market position and expected future demand technology manufacturing process investment opportunity plant economics and project financials.

Salt is an essential ingredient for the survival of all living creatures including humans. Solar salt production is the process in which naturally occurring salt water from a sea lake etc is channeled into a series of shallow interlocking ponds. Project report on iv fluid dextrose saline project report on iv fluid dextrose saline includes present market position and expected future demand technology manufacturing process investment opportunity plant economics and project financials.

Dextrose glucose 5 and normal saline sodium chloride or common table salt 8 5 grams per 100 ml of distilled water have the same tonicity or concentration of the rest of the body fluids that is they will do no harm to the rest of the fluids of the body whereas saline or 9 ns iv solution is used as the universal fluid replacement in. 238000000034 methods methods 0 000 title 1. This process generates a waste effluent that concentrates all the impurities removed from the water.

In the 1860s a procedure known as the michigan process or the grainer process was invented in which salt water was heated by steam running through pipes immersed in the water. Next let the solution boil for 15 minutes then allow it to cool before using it. Project report on saline water dextrose solution i v.

The ultra pure water used is generally obtained by subjecting water from the distribution network or from other sources to a treatment process. Fluid in plastic bottles project report on saline water dextrose solution i v. 239000011780 sodium chloride substances 0 000 title description 7.

150000003839 salts chemical class 0 000 title description 8. 238000004519 manufacturing process methods 0 000 title description 2. Report provides a comprehensive analysis from industry covering.

239000011901 water substances 0 000 title description 18. Over time the water moves through the sequence of ponds that allow evaporation of water to create brine solutions until the most saturated brines evaporate to form salt crystals. This process is still used to produce certain types of salt.

Its use is practical only in warm climates where the evaporation rate exceeds the precipitation rate either annually or for extended periods and ideally where there are steady prevailing.

These extra hard crystalline small pieces are used for the manufacture of single and multistone traverse dressers. Unlike natural diamonds mcd logs have a.

Doubts Over Synthetic Diamond Producers Eco Friendly Claims Jeweller Magazine Jewellery News And Trends

Niobium crucibles for synthetic diamond manufacturing.

Synthetic diamond manufacturing machine. Morgan technical ceramics as diamonex scio diamond technology corporation. List of synthetic diamond manufacturers. Lotus diamond cutting machine.

Pure carbon crystallized in an isotropic 3d form. Synthetic diamonds are made at about 300deg c but usually in a pressure vessel using microwave radiation and a seeding crystal. De beers through a subsidiary called element six diamond foundry.

Element six luxembourg a manufacturer of synthetic diamond for over 25 years offers insight about cvd diamond and the synthetic diamond market. Eons ago when humans were unknown about the precious treasures which were developing beneath the surface of the. Pure grown diamonds formerly gemesis scio diamond technology corporation colorless tairus.

Manmade diamonds for use as gemstones are grown by hpht 34 or cvd 97 methods and currently represent approximately 2 of the gem quality diamond market 98 however there are indications that the market share of manmade jewelry quality diamonds may grow as advances in technology allows for larger higher quality manmade production on a more. Synthetic diamonds are different from both natural diamond which is created by geological processes and diamond simulant which is made of non diamond material. Small prisms with a square base.

Cvd or synthetic diamonds have rung over our ears for. Please use one of the following formats to cite this article in your essay paper or report. You can make diamond as big or small as you want by growing them in a chemically neutral environment nobel gas nitrogen using co2.

Wd lab grown diamonds. Check out wikipedia has an article about them. Adrian wilson head of the firm s technologies.

The mcd logs are made from a single crystal of synthetic diamond having a 8 000 to 9 000 knoop hardness. Synthetic monocrystalline diamond mcd logs. Understanding lab grown diamonds.

Synthetic diamond also referred to as laboratory grown diamond laboratory created diamond or cultured diamond is a diamond made of the same material as natural diamonds.

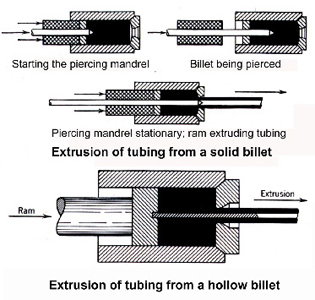

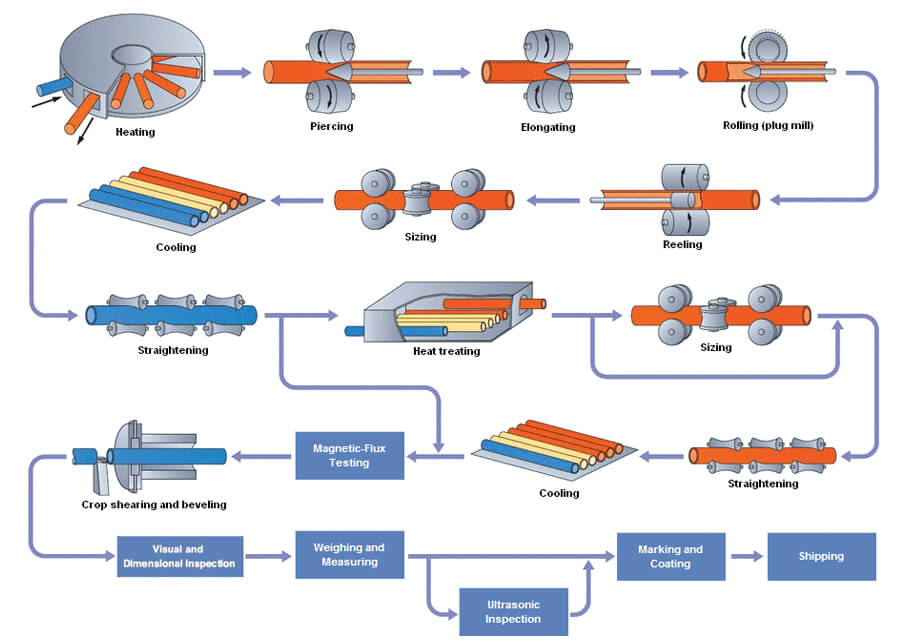

And jiangsu xingrong hi tech co ltd. Next the copper pipe is cleaned using water and or solvents.

Innovations How Do They Do That Making Copper Plumbing Tube

The newly created copper pipe is fed through a series of dies where it s cut into one or more specific sizes.

Copper tube manufacturing process. The manufacturing process the process of extracting copper from copper ore varies according to the type of ore and the desired purity of the final product. Advantage of copper tube manufacturing process. Advantage of copper tube manufacturing process.

Copper pipes are manufactured in three basic steps. Typical copper tube manufacturing processes are as below. Manibhadra fitting copper fitting manufacturer in india copper pipes dealers in india and cupro nickel fitting manufacturer in india.

Each process consists of several steps in which unwanted materials are physically or chemically removed and the concentration of copper is progressively increased. The final step in the manufacturing process of copper pipes involves resizing and cleaning. Continous casting and rolling continuously casting and rolling due to melting processes casting milling the surface rolling these processes form a continuous chain.

Suitable for small batch and multiple specification. Copper tube production process a. Copper pipe and tube production line machine.

Products are widely used in the cable communications rail transit new energy and electric vacuum industries. Typical copper tube manufacturing processes are as below. Now that we have the basic shape for the copper tubing it s time to push it out of the cast.

Once it has cooled and solidified a large machine called a piercing mandrel drills a hole in the copper creating the inside of the tubing. A ram forces the copper rod through an extrusion pipe creating a long hollow tube. Mxr is a joint venture between mueller industries inc.

We manufacturer high quality of copper fitting in india copper tube manufacturing process manibhadra fittings. Jiangsu mueller xingrong copper industries ltd.

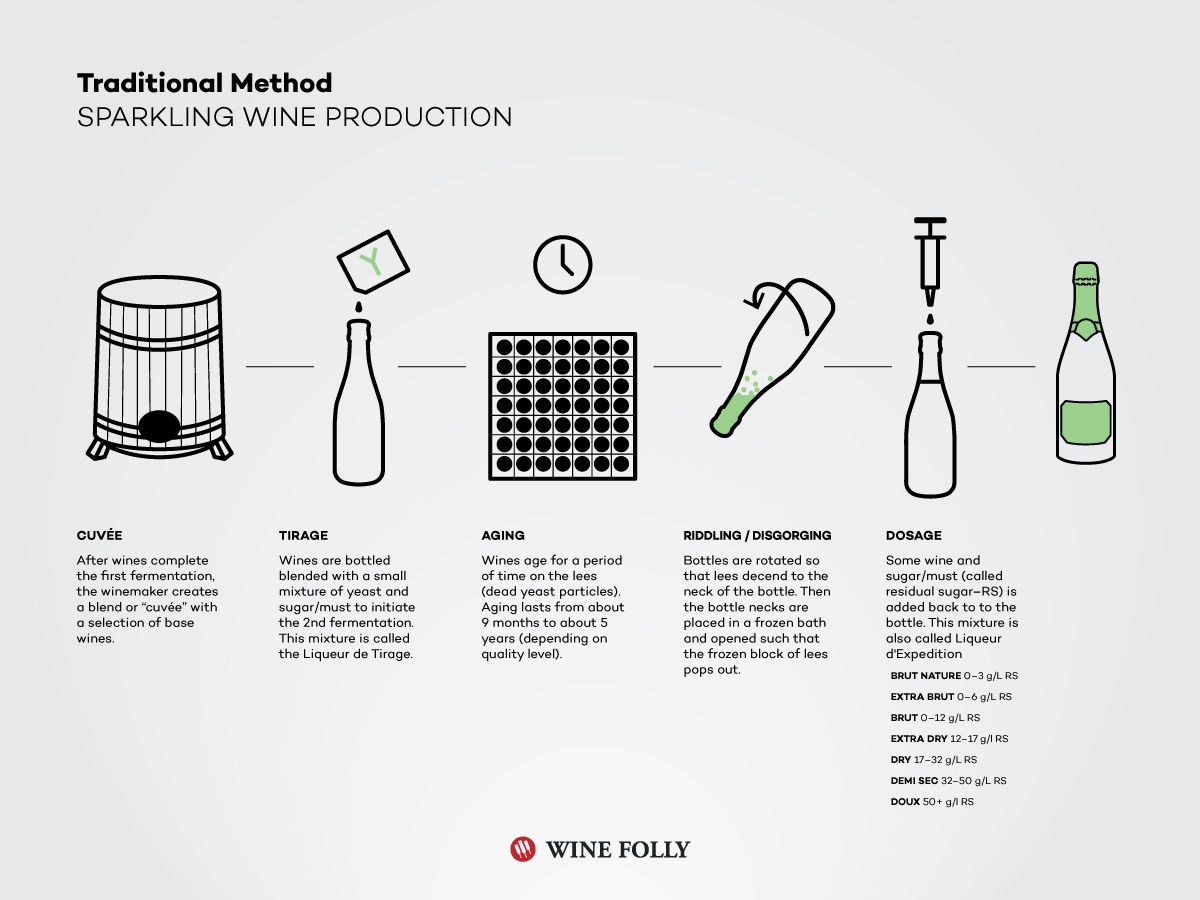

Lees ageing following the completion of the secondary fermentation the wine will then begin a period of ageing in bottle where the wine will interact with the dead yeast cells lees and which will greatly influence the flavor and texture of the finished champagne. Learn how grapes make their way from vineyard to bottle through pressing fermentation blending ageing riddling disgorgement and dosage all while learning about the grapes soils and regions from the champagne region of france.

How Sparkling Wine Is Made Wine Folly

15 describes each in detail see figure below.

Manufacturing process of champagne. Learn more about the crucial steps. And 5 for demi sec the sweetest type of champagne. The key process in producing champagne is a second fermentation that occurs in a sealed bottle it creates the carbonation.

The different sub areas of champagne have different so called top soils which together with the climate are. The process itself is though as turning grape juice into liquid gold takes a lot of time and effort. From picking the grapes to bottling the final product.

The other two environments are continuous process and batch process. So you might say the list of champagne ingredients is not too elaborate. Grande champagne the area around the towns of cognac and seconzac yields the most delicate and fragrant brandy.

This episode covers the entire process of winemaking in champagne. The most expensive champagnes are made from cuvées from grand cru vineyards in the champagne region. 1 is added for extra sec.

This procedure results in the formation of a plug of frozen wine containing the dead yeast cells. The key steps are described below. Not every sparkling wine is champagne but every champagne is a sparkling wine.

It provides from the beginning the sufficient amount of acidity that is essential for the whole process. Grapes in the petite champagne which surrounds grande champagne on the southwest and east are faster to mature and less subtle in taste. Have you ever wondered how champagne is made.

The manufacturing process pressing 1 the grapes are carefully loaded into the press a square wooden floor surrounded by adjustable wooden rails and topped by a heavy oak lid. The cuvée is the base wine selected to make the champagne. The champagne bottle is kept upside down while the neck is frozen in an ice salt bath.

During the production process champagne makers add yeast sugar and wine they reserved from other years vin de réserve. Goldense group inc. The disgorgement is the final step in the production of champagne.

The manufacturing process pressing the grapes 1 the grapes are pressed and the juice is. The art of champagne manufacturing. Here is a quick and easy reference guide that walks you through the process visually in 9 easy steps.

The 5 types of manufacturing processes md sept. This process is known as autolysis.